Types of kitchen cabinet doors: a complete guide.

In the United States, kitchen cabinet doors (or “fronts”/“faces”) have their own structural features and standards. In this article, we will break down the main types of doors: Slab (flat panel), Shaker, Raised Panel, and others.

We will explain how they are built, what materials are used, and what professional terms mean (for example, stile, rail, cope & stick).

Flat doors (Slab panel)

Style:

Modern, minimalist.

Slab fronts (also called flat-panel doors) are the simplest style in form. The door is a single flat panel without frames, raised profiles, or decorative recesses. This style is chosen to create a clean, uncluttered interior.

Construction and Material Features.

The door consists of one solid piece of material. There are no vertical stiles or horizontal rails. The edges are usually finished with matching edge banding.

Technically, slab doors require materials that maintain geometry and resist warping caused by humidity and temperature changes. Large solid wood doors can warp, which is why modern manufacturers use engineered wood panels — they are far more stable and suitable for flat smooth surfaces.

Main Core Materials for Slab Doors:

- MDF (Medium Density Fiberboard)

The optimal core for solid slab doors: uniform structure, perfectly smooth paint-grade surface, and high stability; - Particleboard

Often used with decorative surfaces such as TFL/HPL. A practical and stable choice for economical and commercial projects; - Enhanced Plywood / Lumber Core (Plywood / Armor Core)

Provides strength, stability, and works perfectly under veneer or other premium finishes.

Main Types of Decorative Surfaces:

- TFL (Thermally Fused Laminate)

A decorative layer fused into the core. Offers ready-to-use wood or stone textures, combining durability and affordability; - HPL (High-Pressure Laminate)

Thick, impact-resistant, and water-resistant. It can be glued to the core or supplied as prefabricated sheets with their own substrate. Used when increased durability is required; - Acrylic

Glossy or super-matte panels with a glass-like look — ideal for modern minimalist kitchens; - Natural Wood Veneer

A thin layer of real wood applied to a stable substrate (typically MDF or plywood). Offers the look of solid wood with far greater stability, and can have lacquered, oiled, or matte finishes.

Slab fronts are often paired with shaker doors. For example, lower cabinets may use slab drawer fronts while upper cabinets use framed doors, or vice versa. This creates a balanced look and cost. Additionally, slab fronts are easy to clean — they have no grooves where dust can accumulate.

Shaker doors

Style:

Universal, U.S. classic, transitional.

The Shaker door is the most popular style in America. Inspired by the craftsmanship of the Shaker community, it features clean straight lines with no excessive ornamentation.

5-Piece Frame Construction.

The door consists of a frame and a recessed center panel. The classic five-piece door includes:

• two vertical stiles;

• two horizontal rails (top and bottom);

• one center panel.

All parts are joined together, forming a single door.

Framed construction has been the foundation of traditional American cabinetry since the 19th century. Why? Because a frame made of relatively narrow boards is much more stable than a wide solid piece. The center panel “floats” inside the grooves and can move slightly with wood expansion and contraction without deforming the door.

This floating method allows the panel to expand in humidity and contract in dryness without cracking or warping the entire door, as the grooves compensate for movement. This makes the design ideal for natural wood. The solid frame also adds rigidity and reinforces the crafted character of the door.

Construction and Joinery

Traditional Shaker: a framed door with universal proportions. The width of stiles and rails is typically 2¼", 2½", or 3".

Two main joinery methods are used:

• Cope & Stick — classic right-angle 90° joint. Rails fit into stiles via tongue and groove. Suitable for Shaker and simple profiles.

• Miter Joint — 45° joint offering a seamless continuous profile around the frame. Used for refined or decorative doors; requires high precision.

Materials:

• For stain: Solid wood frame + veneered panel.

• For paint: MDF (especially for the center panel); frame often solid wood.

• Laminate: TFL/HPL frames and panels imitating wood texture (available only for traditional wide-frame Shaker).

Slim shaker doors

Slim Shaker: a modern variation featuring a narrow frame (½–¾"). The thinner lines visually enlarge the center panel, giving a lighter, more minimalistic appearance.

Construction and Joinery

Slim Shaker frames are typically made of solid wood, while the center panel is MDF for painted finishes, or MDF/particleboard/plywood for natural wood veneer finishes. It is technically challenging to produce this door style using laminated surfaces.

Mitered Shaker: the frame joints are mitered at 45°.

The construction and all other characteristics are the same as those of a traditional Shaker.

Raised Panel Doors

Style: Traditional, classic, rich.

This is also a 5-piece door, but with one key difference: the center panel is not flat — it is raised. The panel edges are machined so that the center protrudes forward, creating depth and shadow.

Profile: The center panel is thickened and has a decorative edge. The inner edge of the frame is often detailed (sticking).

Joinery:

Same as Shaker — Cope & Stick or Miter Joint.

Materials:

Typically solid wood frames and either solid wood or MDF panels.

Limitation: True raised panels cannot be made from TFL or HPL because they cannot replicate complex 3D shapes.

Thermofoil Doors (RTF / Vinyl-Wrapped Doors)

Style:

Budget-friendly imitation of classic or modern styles.

Thermofoil (RTF — Rigid Thermofoil) is a technology where a vinyl film is vacuum-pressed over a routed MDF substrate.

Pros: Imitates painted wood (Shaker or Raised Panel) at a lower cost. The finish is seamless — the film wraps the face and edges.

Cons: Heat-sensitive. The film can delaminate near ovens without protective heat shields.

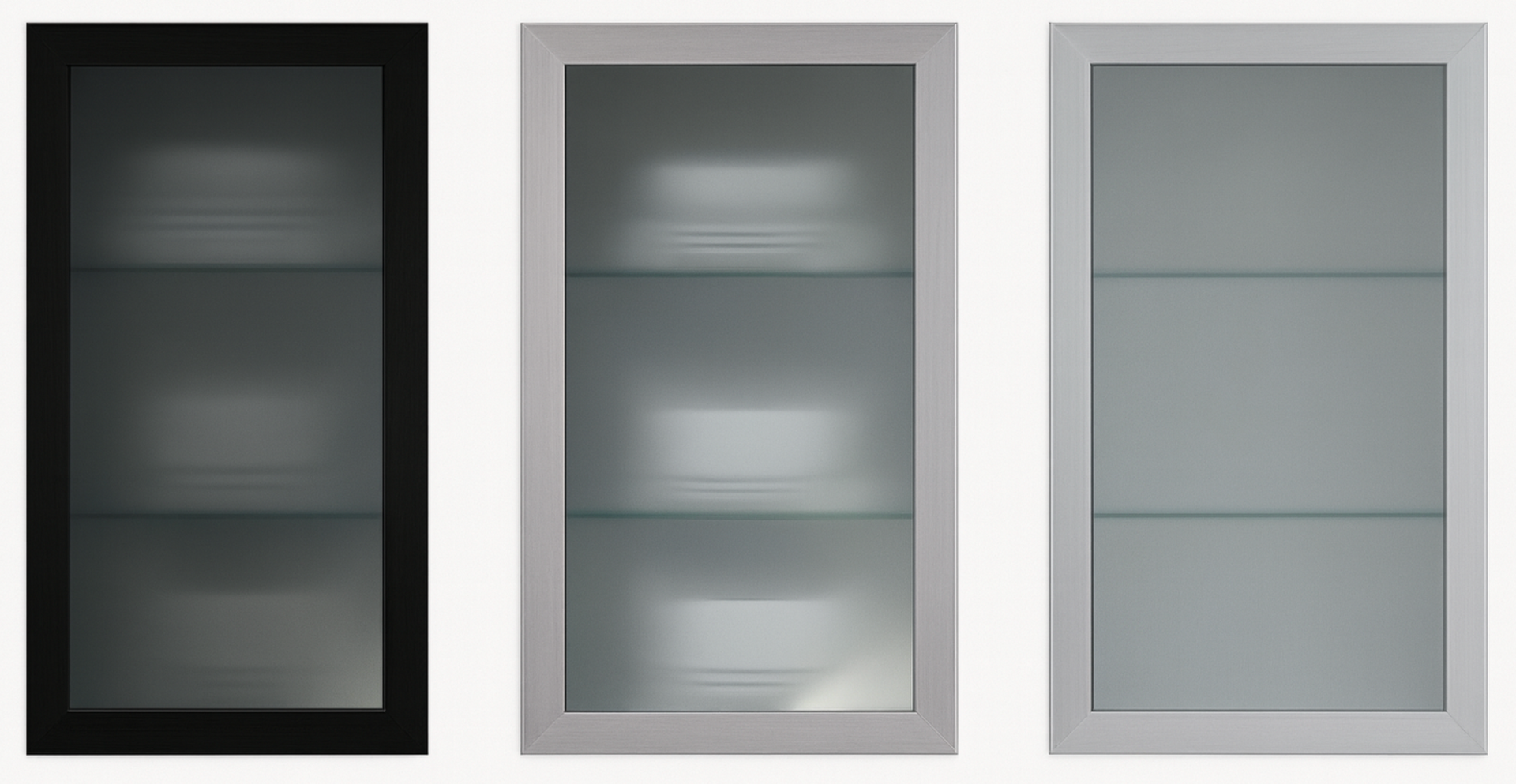

Aluminum frame Glass Doors

Aluminum door frames with glass inserts bring a sleek, glossy finish that enhances a flawless modern design. These durable frames are custom-made to size, available in two finish options and six door design variations. Each order is carefully assembled using clear or laminated glass to ensure a pristine, high-end result.

Style:

Modern.

An accent solution ideal for upper cabinets. The door features a slim anodized aluminum frame with an inserted glass panel, typically frosted or tinted.

Effect: The metallic frame adds contrast, while the glass visually lightens the upper cabinetry, creating a sense of openness and sophistication.

Available Frame Finishes:

Aluminum frame doors are offered in the following premium finishes:

- Brushed Black – A deep, matte metallic black with fine linear texture for a bold, contemporary look;

- Brushed Steel – A soft silver-gray tone with a subtle brushed texture, evoking a modern industrial style;

- Anodized – A clean, light metallic finish with a smooth, satin appearance that works seamlessly in minimalist interiors.

Each finish is applied to precision-engineered aluminum frames, enhancing durability and contributing to a sleek, high-end aesthetic. These finishes are designed to complement a variety of modern kitchen styles and integrate beautifully with both neutral and bold material palettes.

Available Glass Insert Options:

• Black Glass

• Bronze Glass

• Bronze Solar Cool

• Light Gray Glass

• White Laminated Glass

Wood frame glass doors / mullion doors

Designer wood-framed doors with glass inserts offer a sleek, glossy finish that complements flawless contemporary design. These sturdy wooden frames are custom-made to size, available in a range of finish options and two central glass panel styles.

Style:

From Classic to Farmhouse

A stylish variation of the standard framed cabinet door, where the center panel is replaced with glass.

Mullion Doors: The glass is divided into sections by wooden grids, commonly seen in traditional and transitional kitchens.

Without Mullions: A single uninterrupted glass insert creates a cleaner, more structured, and modern aesthetic.

These doors function as elegant display fronts, adding depth, lightness, and architectural interest to cabinetry.

Ideal for use in upper cabinets, buffets, display hutches, built-ins, and decorative sections of kitchens, dining rooms, or living spaces.

Center Glass Insert Options:

Available in 1/4" thickness:

- Clear Glass

- Laminated Frosted Glass (frosted effect)

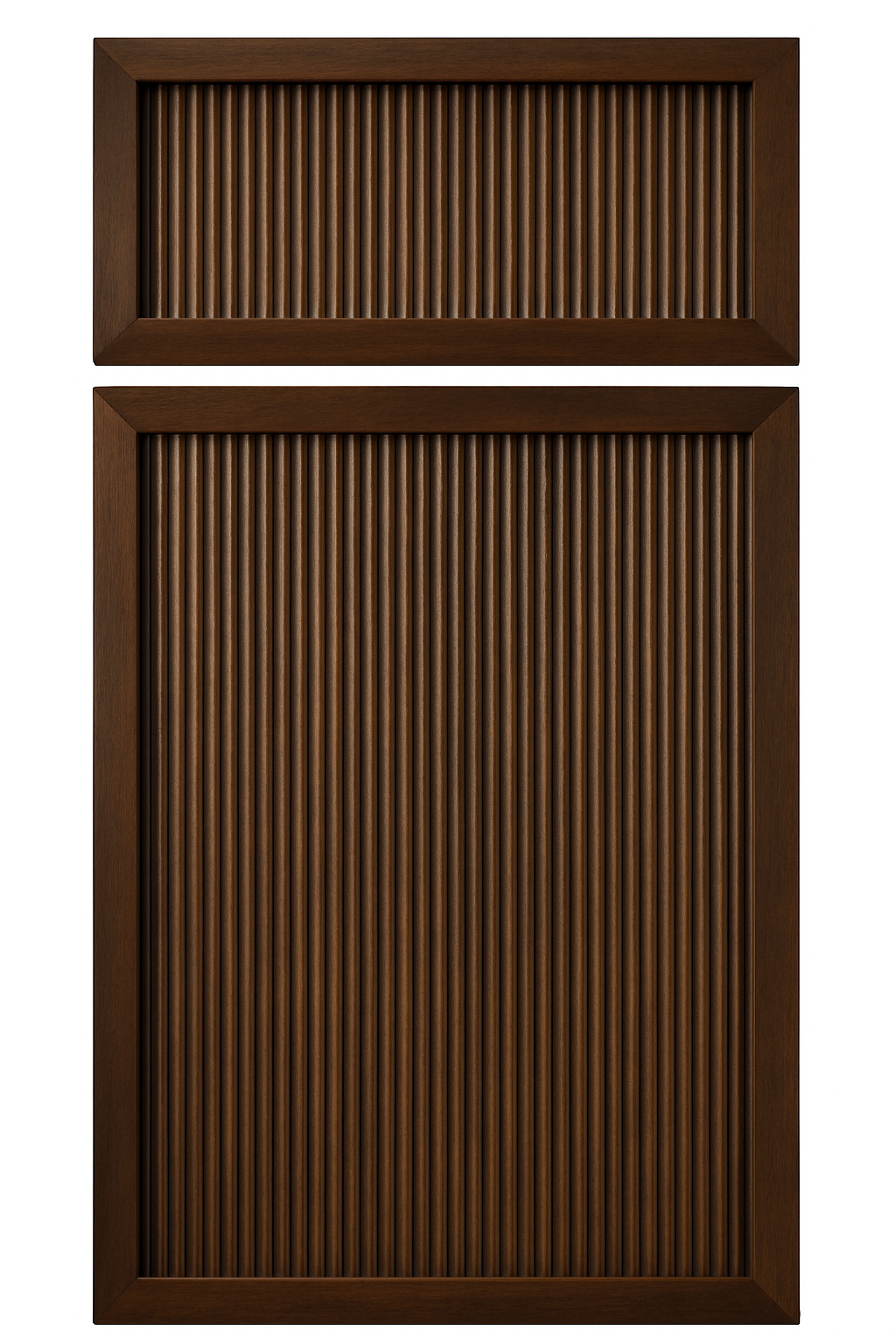

Fluted cabinet doors

Fluted cabinet doors (also known as Reeded or Ribbed) are a trending solution in contemporary furniture design, bringing texture, rhythm, and architectural expression. They are ideal for kitchen fronts, buffets, sideboards, and built-in cabinetry.

Depending on design and manufacturing method, fluted fronts are produced in two main types:

Solid Slab with Fluting

- Core: MDF or furniture-grade wood panel;

- Fluting: Vertical grooves (U-shaped, V-shaped, or rounded), CNC-machined;

- Finish: Matte/gloss lacquer, veneer, varnish, or oil;

- Application: Minimalist and modern styles.

Framed Construction with Fluted Center Panel

- Frame: Vertical stiles and horizontal rails (solid wood or veneered MDF);

- Panel: MDF or plywood with full-height vertical fluting;

- Joinery Options: Cope & Stick — classic tongue and groove at 90°, miter Joint — seamless 45° join for a clean, elegant look;

- Details: Optional edge concealment, decorative routing, recessed panels.

Advantages

- Modern premium aesthetic;

Visually elongates surfaces through vertical relief;

Compatible with paint, stain, or natural wood veneer;

Highly adaptable styling — from minimalism to Mid-Century or Art Deco.

Quick guide to materials

Solid Wood: Used for door frames and cabinet face frames.

MDF: Premium paint-grade material; core for TFL, HPL, and veneer.

Plywood: Preferred for cabinet boxes and as a substrate for laminate or veneer.

Particleboard: Budget material for cabinet boxes and laminate substrates.

TFL & HPL: Decorative laminates for modern flat fronts.

Wood Veneer: Thin slices of real wood applied to engineered cores, offering a solid-wood look with greater stability.

Transform your space with custom handcrafted kitchens in Portland

As a custom kitchen manufacturer based in Portland, we follow American cabinetmaking standards and build handcrafted kitchens that meet the architectural, aesthetic, and structural requirements of every project. Our design team works with all materials and door types listed in this guide. Since each project requires a unique balance of strength, aesthetics, and cost, our designers carefully combine different styles, veneers, laminates, composite materials, and finishes to achieve the most functional and visually harmonious result. Their approach ensures that every kitchen reflects its architectural context while meeting long-term performance expectations.