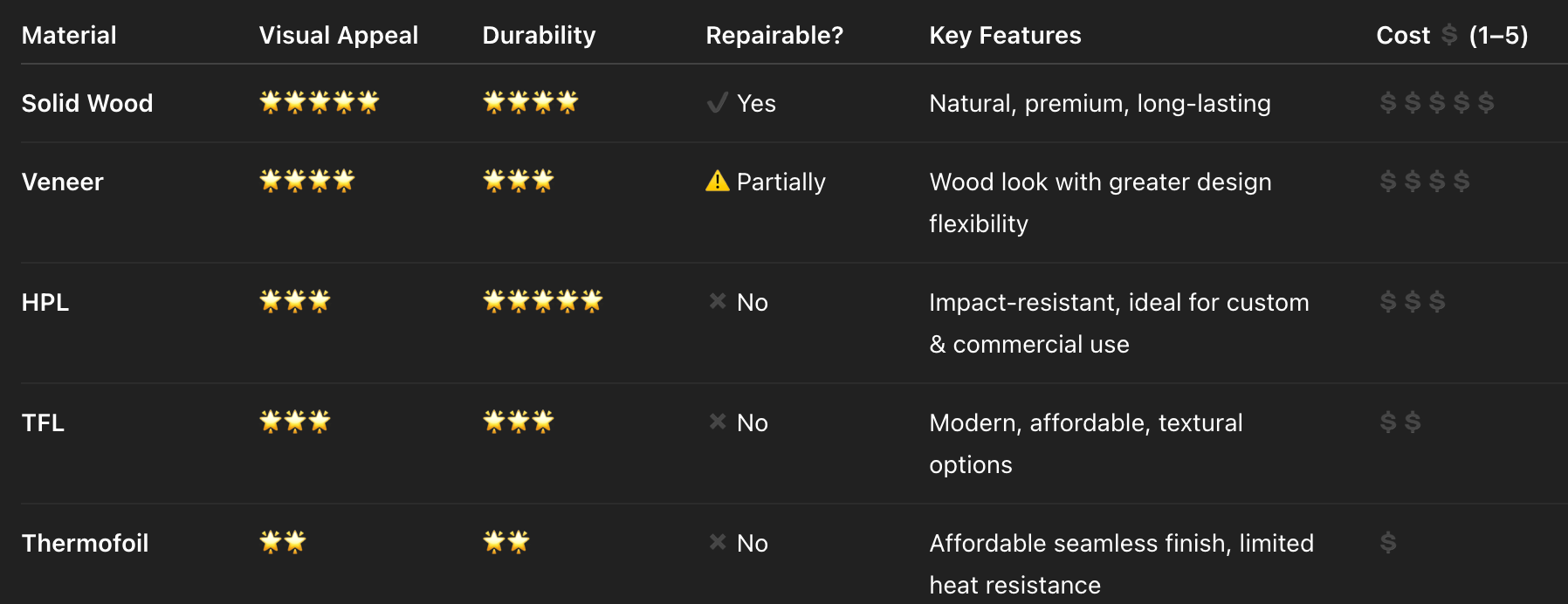

What Are Kitchen Cabinet Doors Made Of? A Clear Guide to Materials.

Cabinet doors are the face of any kitchen. They define the visual style, the sense of quality, and the day-to-day experience of using the space. But behind the appearance lies a key question: what are they made of?

This guide breaks down the 5 most common materials used in U.S. kitchen and built-in cabinetry production. We’ll explain their differences simply — so you can choose with confidence.

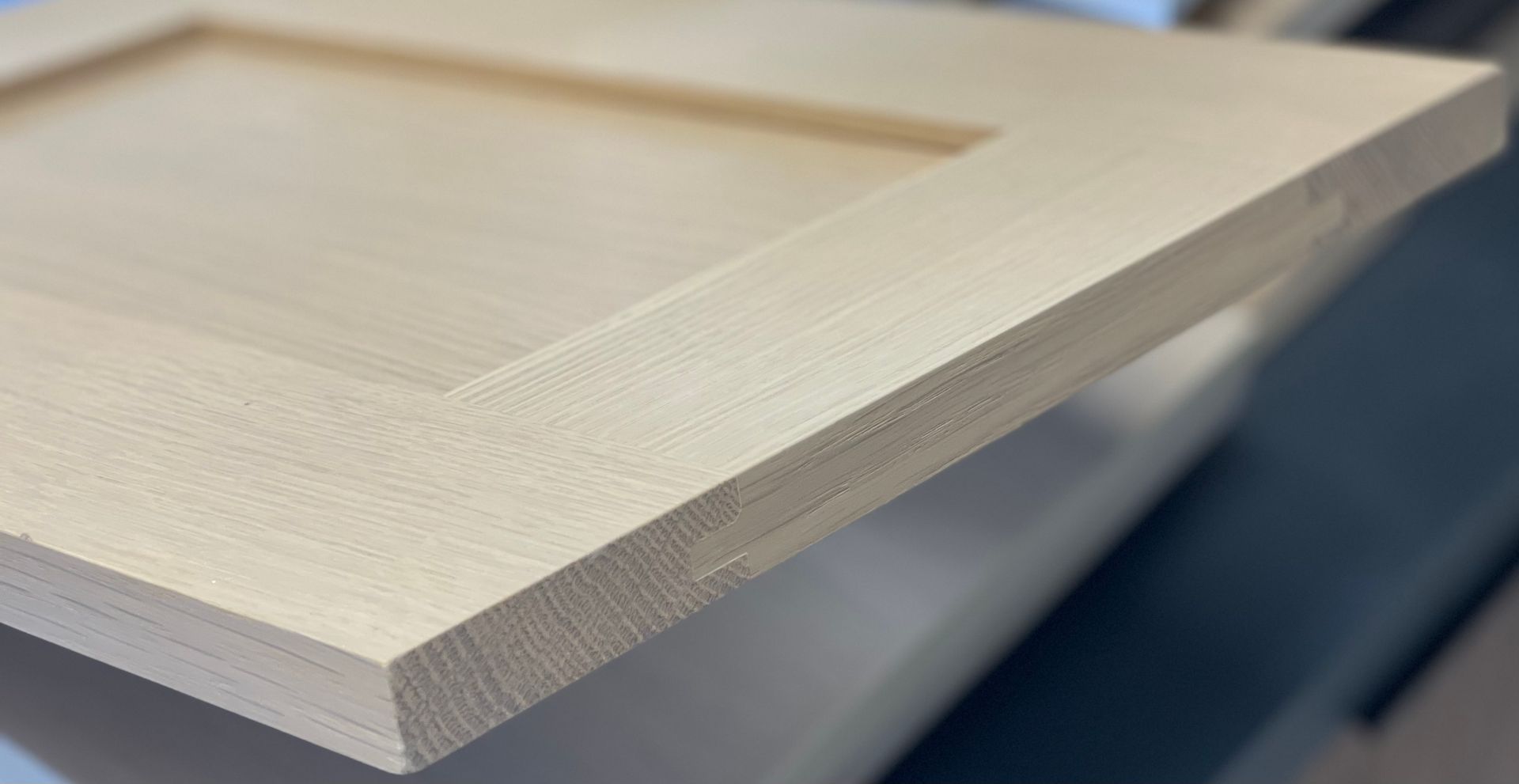

SOLID WOOD

What it is: 100% natural hardwood (commonly maple, oak, cherry, alder, hickory, or walnut), used as solid panels or glued staves.

Pros:

- Authentic look and natural grain

- Can be sanded, refinished, repainted

- Accepts stain, lacquer, or paint

- Long-lasting and premium

Cons:

- Higher cost

- Can warp with humidity fluctuations

- Heavier and more demanding during installation

Best for:

Buyers looking for a timeless, high-end kitchen with the warmth and authenticity of real wood. Ideal for private homes and traditional interiors.

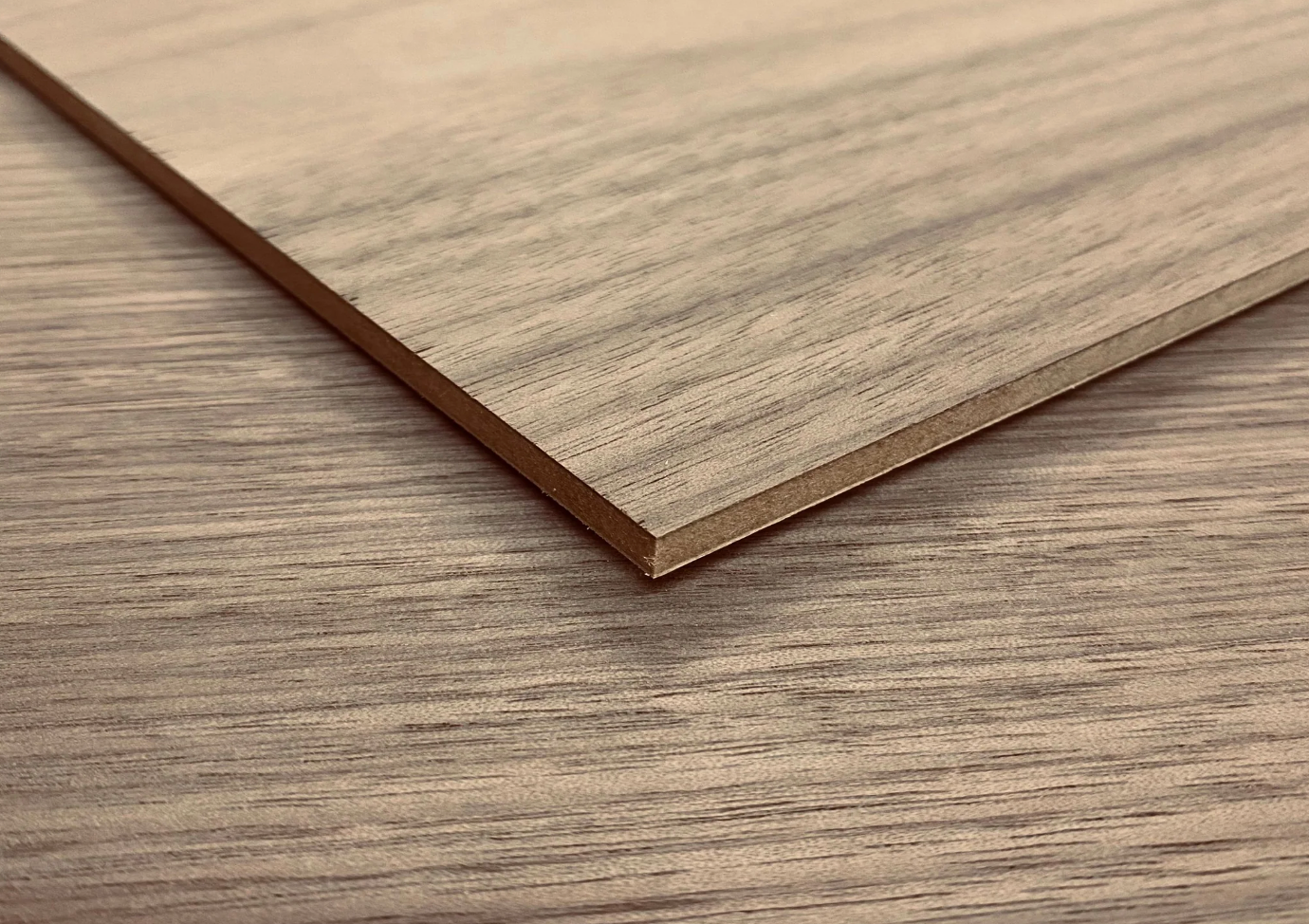

WOOD VENEER

What it is: A thin slice of real wood (typically 0.5–1 mm) bonded to MDF or plywood panels.

Pros:

- Nearly identical appearance to solid wood

- More stable than solid wood under humidity changes

- Can be finished with stain, lacquer, oil — or painted

- Provides a natural wood look at a lower cost

Cons:

- Thin layer requires careful handling during manufacturing and installation

- Limited repair options if deeply damaged

Best for:

Clients who want the visual beauty of real wood with more budget flexibility and design freedom.

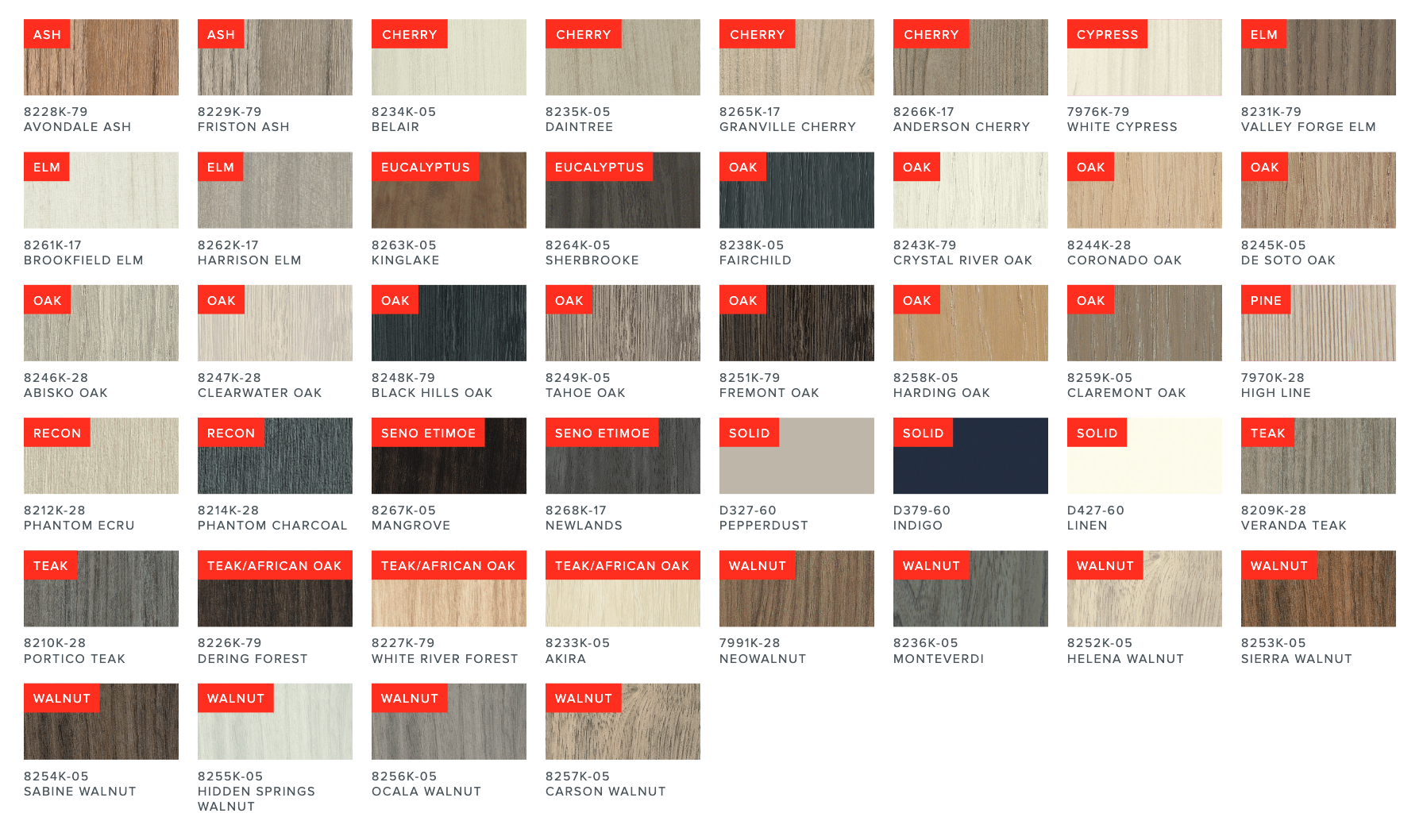

HPL (High-Pressure Laminate)

What it is: Decorative laminate pressed at high pressure and bonded to MDF or plywood.

Pros:

- Exceptionally durable — resistant to moisture, heat, scratches

- Extensive range of textures and finishes — wood grain, stone, concrete, solid colors

- Ideal for high-traffic, high-use environments

Cons:

- Visible edges unless post-formed

- Cannot be repaired if damaged

Commonly used when:

- Custom shapes or cuts are required

- Projects demand precision fitting to non-standard dimensions

- Large surface areas must be covered with minimal seams — perfect for commercial countertops, wall panels, and built-ins

Best for:

Modern kitchens, commercial spaces, and any project requiring strength, dimensional accuracy, and aesthetic flexibility.

TFL (Thermally Fused Laminate)

What it is: A decorative melamine layer fused to a particleboard or MDF core using heat and pressure.

Pros:

- Resistant to everyday wear and light moisture

- Easy to clean

- Wide variety of finishes, including textured, matte, and embossed woodgrains (EIR)

Cons:

- Not repairable if chipped or deeply scratched

- Slightly less durable than HPL

Best for:

Modern residential kitchens, commercial millwork, closets, and built-ins where visual consistency and material stability are key.

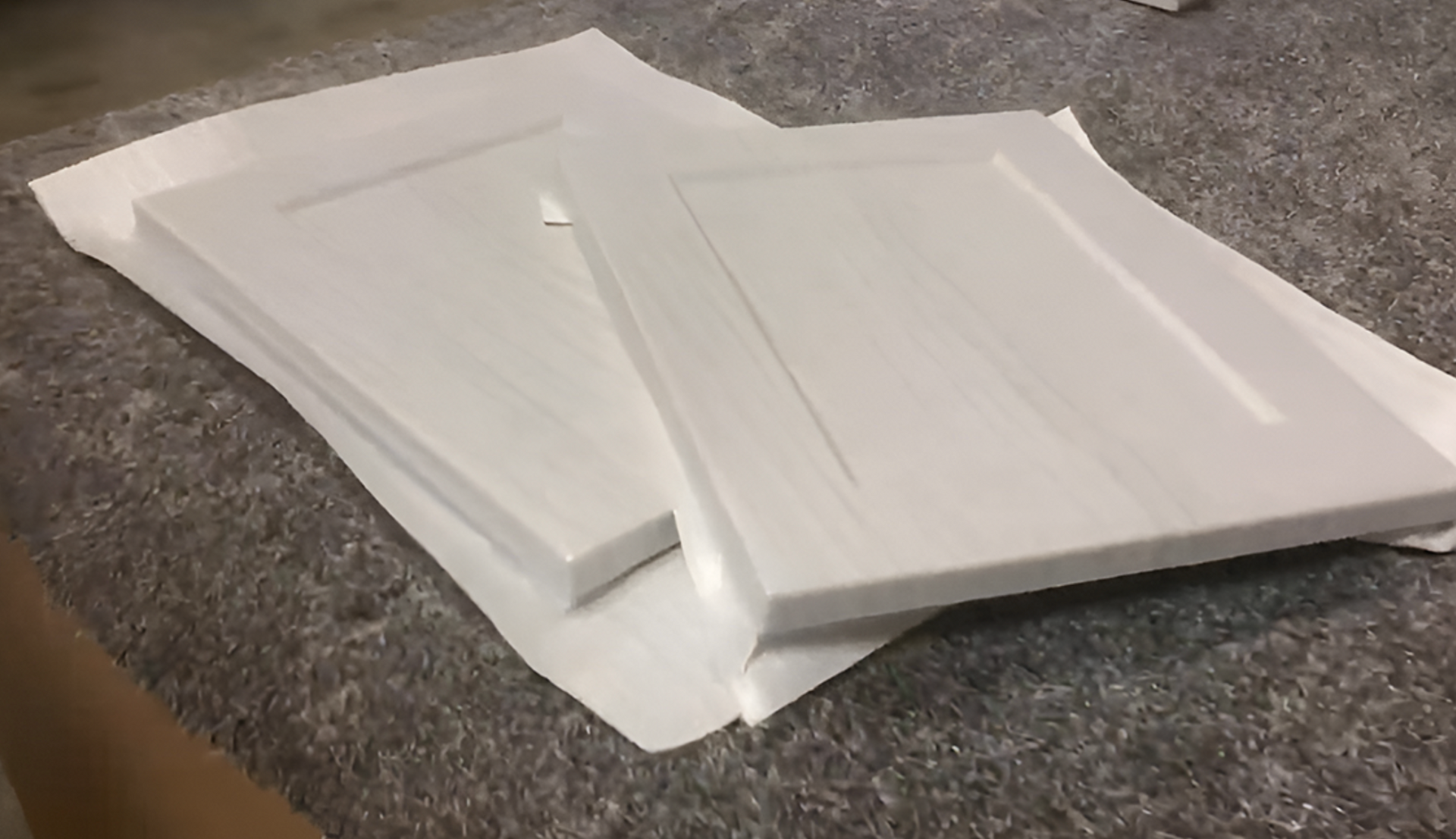

MDF (Medium density fiberboard)

MDF (Medium Density Fiberboard) — a dense, uniform wood-fiber panel widely used in cabinetry for its stability, smooth surface, and excellent machining properties.

Pros:

- The best substrate for painted finishes due to its smooth, non-grain surface

- Machines exceptionally well — ideal for detailed profiling, routing, and 3D designs

- Perfect for Thermofoil doors thanks to consistent density and shape retention

- Used as the core material in ready-made decorative panels laminated with natural wood veneer or TFL/HPL

- Mostly used for the center panels in 5-Piece doors that are intended for painting

- Highly stable — resists warping and cracking under humidity changes

- Uniform structure ensures predictable CNC performance

Cons:

Vulnerable to moisture if the protective finish is compromised

Heavier than particleboard

Not suitable for structural load-bearing components

Best for:

Paint-grade doors and drawer fronts, 5-Piece shaker-style doors, Thermofoil doors, routed and profiled facades, and decorative panels veneered or laminated with TFL/HPL where a stable, smooth, and precise substrate is required.

TERMOFOIL

What it is: A thin vinyl film, vacuum-formed over an MDF substrate, creating a seamless surface.

Pros:

- Smooth, clean, joint-free look

- Affordable

- Wide range of colors, styles, and shapes

Cons:

- May peel or blister with prolonged heat exposure (e.g. near ovens or cooktops)

- Prone to color fading over time

- Not repairable if damaged

- Can crack on curved or bent sections, especially under tension

Best for:

Clients seeking a clean, uniform appearance at an affordable price — suitable for simple geometric cabinetry in low-heat zones.

Pro-Tech Woodworking — smart choices, tailored solutions

We crafts kitchens and custom cabinetry in Portland using all of the materials above — always tailoring solutions to each project while protecting your budget. We’ll guide you through the options, show samples, and explain pros and cons — with no pressure, just clarity.

We carefully balance thoughtful kitchen design, clean engineering, and smart material selection.

— When a space needs smoked oak veneer, we’ll use it.

— When a high-end TFL laminate gives the same effect, we’ll recommend it.

— When large seamless surfaces are required, we’ll go with HPL — with color-matched edges to create visual harmony.

Our goal is to deliver outstanding quality, functionality, and style — all within budget.